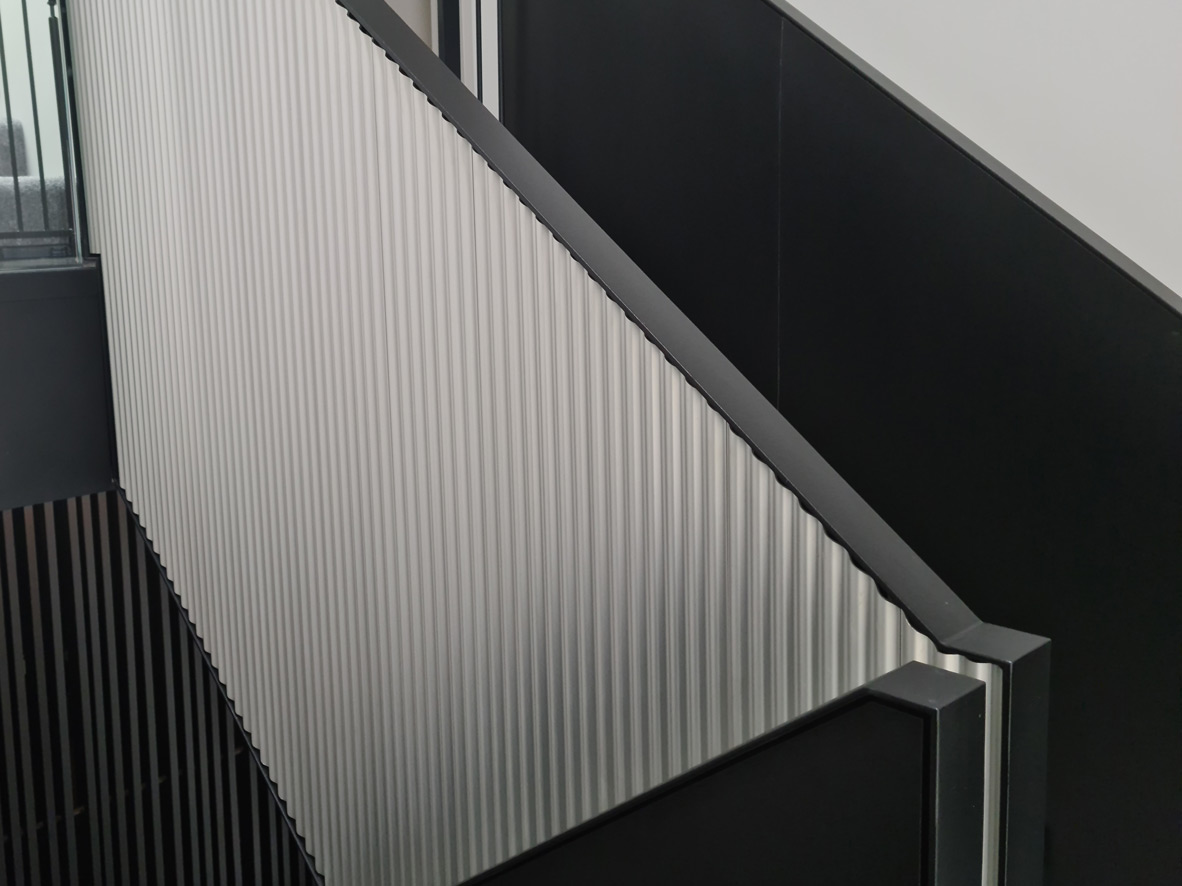

Bespoke Stair Cases

Bespoke Stair Cases

Sneak Peek – full case study available soon

One of the most compelling projects recently comprised of designing, manufacturing and installing two new feature stair cases for two adjacent Edinburgh New Town Mews houses. We set out to push the boundaries in terms of manufacturing and finishing of the steelwork. For the first staircase we wanted to it to be manufactured and finished in blackened mild steel – a process that is fairly well known, however it is less so applied on this scale due to finishing issues. On structures at this scale, it is normally hand applied which can be a very laborious undertaking with a higher chance of failure. In order to ensure consistency, we manufactured custom made steel tanks and used the dipping method – which is normally used on small components such as screws and machine parts. The oxide had to be kept at an ambient room temperature in order to take effect on the steel. This resulted in the overall even finish we were envisaging. The stair treads and landings are a feature in themselves. We wanted a combination of blackened steel and polished concrete without the use of visible steel trays. By means of removable shuttering these were then cast and polished on site. A special thanks should be mentioned to the site manager Charles Smith who is passionate about all things concrete and was spending countless hours to achieve the desired level of finish. The install of the stair components was a challenge – we had to build a custom-made gantry crane in order to lift the heavy prefabricated parts safely into position while navigating through a large, 7-meter-high open void.

Design / Manufacture / Install:

J.Sailer Fabrications

Client:

Andrew Smith / Brendan O. Brien

Tags:

#steelwork #oxide #blackenedsteel #welding #pressbrake #cnc #machining #gantry #polishedconcrete #cad #steeltank #design #bespoke